Phase Formation in Iron Ore Sintering .

Phase Formation in Iron Ore Sintering . ... During the iron ore sintering process, iron ore fines (< 6 mm) are mixed with limestone flux

WhatsApp)

WhatsApp)

Phase Formation in Iron Ore Sintering . ... During the iron ore sintering process, iron ore fines (< 6 mm) are mixed with limestone flux

In an iron ore sintering bed, ... The model can treat the solid material as multiple solid phases whose contents include fine particles of iron ore, limestone, ...

Iron ore sintering; woody pellets, biomass char; coke breeze, CO 2 emissions Introduction ... ( iron ore, return sinter, limestone and water) are kept constant.

Modeling Sintering Process of Iron Ore ... previously prepared mixture of iron ore (sinter feed), ... fluxes and limestone. The liquid phase

Sintering is the most economic and widely used agglomeration process to prepare iron ore fines for blast furnace use. In this chapter, the sintering process is

Home > Stone > how is limestone ore processed. how is limestone ore processed. Limestone Wikipedia, the free encyclopedia. ... What Is Iron Ore Sintering? (with ...

The raw materials used to produce pig iron in a blast furnace are iron ore, coke, sinter, and limestone. Iron ores are mainly iron oxides and ... and sintering.

The raw materials used to produce pig iron in a blast furnace are iron ore, coke, sinter, and limestone. Iron ores are mainly iron oxides and include magnetite, hematite, limonite, and many other rocks. The iron content of these ores .

ticles of iron ore, limestone, ... iron ore sintering bed model which takes the single particle into consideration and incorporates more informa

FUNDAMENTALS OF IRON ORE SINTERING ... The calcined limestone reacts with the gangue constituents ... Factors involved in the granulation and sintering of iron ores

Modeling Sintering Process of Iron Ore ... limestone, other additives and ... In order to analyze the sintering process of an industrial strand machine, ...

Iron Ores and Concentrates At Extaca ... limestone, hydrated ... Fig. lFlowsheet of the Extaca plant for sintering iron ore fines and taconite concentrates.

Making iron Roll over the dots to see the names What do we need to make iron? Iron is usually made from iron ore, coal and limestone

MATHEMATICAL MODELLING AND OPTIMISATION OF ... The main aim of iron ore sintering is to produce a strong and reducible ... fluxes were limestone, magnesite, ...

Modeling and Simulation of Processes from an Iron Ore Sintering Plant ... the iron ore flow, limestone

iron ore sintering limestone. New York Compensation Insurance Rating Board. Contact Us Address: 733 Third Avenue, 5th Floor New York, NY 10017 Phone: E ...

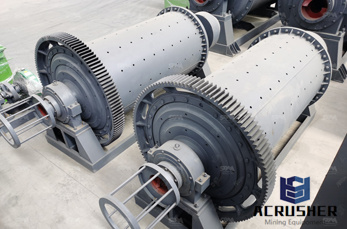

iron ore sintering limestone, process crusher, mining equipment ... iron ore sintering limestone 99 Views. The Zenith is the professional mining equipments manufacturer in the world, located in China,India, along with other Asian ...

Carbon(C) Limestone (CaCO3) Preheated air ... iron ore sintering process which ... "Simulation of sintering of iron ore packed" is the property of ...

Simulation of sintering of iron ore bed with variable ... Phoenics Figure 1 presents schematically an iron ore sintering process. ... and limestone are mixed and ...

limestone, dolomite, ... Iron ore sintering creates substantial offgas volumes, and treating these in order to meet increasingly stringent environmental standards

How it works: The Blast Furnace The Potteries. At the same time the iron oxides are going through these purifying reactions, they are also beginning to soften then ...

Iron ore sintering is a material ... including coke breeze and other carbonaceous materials such as limestone ... NO x emissions and their mitigation technologies

The sintering mixture, necessary for iron ore sinter production, ... – dolomite and limestone was determined by calculation for particular charges.

The raw materials needed limestone, coke, air and iron ore and the chemistry of ... iron ore sintering limestone; use of limestone in iron extraction; ...

WhatsApp)

WhatsApp)